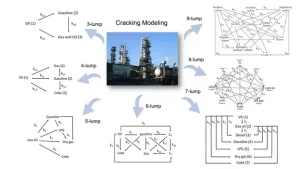

The development of an appropriate kinetic model for cracking reactions is essential for simulation and process optimization. These results are to be potentially used for proper reactor design. The complexities of oil gas inlet combinations have led to an increase in the challenges while defining and depicting kinetics on an intrinsic scale. Hence, complicated chemical […]

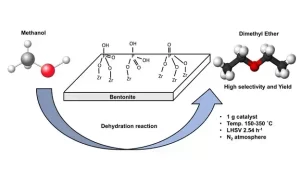

Modification of sodium montmorillonite was conducted using zirconium phosphate. The effect of a series of phosphate precursors such as dihydrogen phosphate, diammonium hydrogen phosphate, and sodium phosphate was observed. The catalyst was used in the conversion of methanol dimethyl ether using 1 g of catalyst at a temperature range of 150-350 ˚C with a Liquid […]

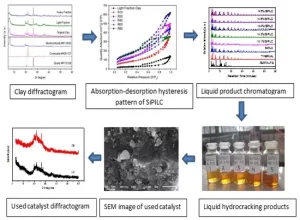

Synthesis of Ni/SiPILC (Silica Pillared Clay) catalyst based on light fraction clay for hydrocracking of High-density Polyethylene (HDPE) plastics into liquid fuels has been carried out. The SiPILC was synthesized using CTAB and TEOS by varying the TEOS/clay mole ratio. The Ni metal was impregnated on the SiPILC with a variation of 2, 4, 6, […]

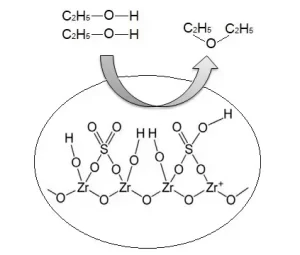

SO4/ZrO2 heterogeneous acid catalyst was prepared by wet impregnation method from ZrO2 precursor involved variations in H2SO4 concentration (0.5; 1.0; 1.5 M) and calcination temperature (400, 500, 600 ℃) to yield catalyst with the highest acidity value. The catalysts produced were characterized using Fourier Transform Infrared (FTIR) spectrometer, X-Ray Diffractometer (XRD), Scanning Electron Microscope-Energy Dispersive […]