Lump Kinetic Method in Solving Kinetic Problems and Cracking Reaction Mechanism: A Review

Authors

Abstract

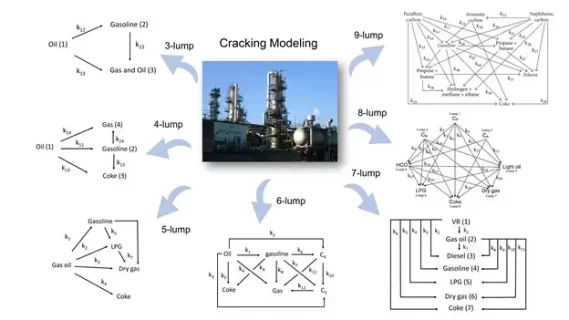

The development of an appropriate kinetic model for cracking reactions is essential for simulation and process optimization. These results are to be potentially used for proper reactor design. The complexities of oil gas inlet combinations have led to an increase in the challenges while defining and depicting kinetics on an intrinsic scale. Hence, complicated chemical reaction circumstances are characterized by combining many possible pathways into more modest groups of comparable chemical substances. In addition, cracking kinetic demonstrations is frequently carried out in lumped forms. This is due to the complex nature of the feedstock, which is known to contain enormous hydrocarbon associated with series and parallel reaction networks. The representation of complicated compounds by consolidating a large chemical component into small amounts of apparent components has been generally utilized in industry to generate a straightforward approach to stoichiometry, thermodynamics, and kinetics. Considering the importance of this lumped method, this study focused on studying the development of a kinetic lump approach to solve kinetic problems and cracking mechanisms.

Highlights

- The lump kinetics model of cracking is intended to be useful for petrochemical operations

- The lumping approach may produce dependable results in predicting product distribution

- The lumping method could predict the parameter kinetic adequately than the conventional method

- The higher the degree of the Lump technique, the better the model that could explain the cracking mechanism