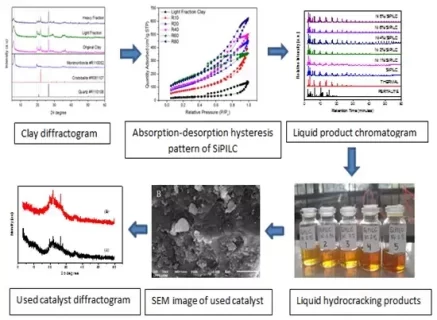

Synthesis and Catalytic Performance of Ni/Silica Pillared Clay on HDPE Plastic Hydrocracking to Produce Liquid Hydrocarbons as Fuel

Authors

Abstract

Synthesis of Ni/SiPILC (Silica Pillared Clay) catalyst based on light fraction clay for hydrocracking of High-density Polyethylene (HDPE) plastics into liquid fuels has been carried out. The SiPILC was synthesized using CTAB and TEOS by varying the TEOS/clay mole ratio. The Ni metal was impregnated on the SiPILC with a variation of 2, 4, 6, and 8 wt% of Ni. Hydrocracking of HDPE plastic was carried out using catalysts in a semi-batch stainless steel reactor. The liquid cracking product was analyzed using GC-MS. The results showed that the clay consisted of Montmorillonite, Cristoballite, and Quartz minerals. The highest specific surface area of 571 m2/g was showed by the SiPILC treated by TEOS/clay mole ratio of 60. Ni 2%/SiPILC achieved the best performance catalyst with the highest acidity of 1.327 mmol/g that produced a liquid fraction of 45.50% (gasoline 55.03 % and diesel 44.96 %) at hydrocracking temperature 450 oC for 1.5 h. The Ni 2% /SiPILC catalyst still performed well after the fifth hydrocracking run, producing a liquid fraction of 41.08 %.

Highlights

- Montmorillonite mineral refinery from early clays.

- SiPILC synthesis based on the light fraction of clay with the best TEOS/clay mole ratio = 60.

- Ni 2%/SiPILC catalyst has the best catalytic performance in the HDPE plastic hydrocracking process to produce liquid products with fuel characteristics.

- The best conditions for the HDPE plastic hydrocracking process with Ni2%/SiPILC catalyst at a temperature of 450oC, 1.5 hours, the liquid product is selective for the gasoline and diesel fuel fractions.

- Reusing five times of Ni 2%/SiPILC catalyst showed a decrease in catalyst activity.