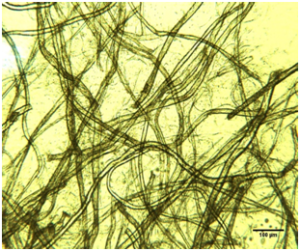

This research used an oven and spray drying method to dry nanofibrillated cellulose (NFC) and evaluates its effect on polylactic acid (PLA) nanocomposite properties. As shown by atomic force microscopy (AFM), the average size of nanocellulose in the spray-dried sample (NCSD) was 84-96 nm. However, the average size of nanocellulose obtained from oven drying was […]

Hydroxyapatite is a biocompatible ceramic and reinforcement for bone implantations. SEVA/HAP composite content HAP filler with difference particle sizes were designed. Mechanical tests like tensile modulus, UTS, strain at break and biodegradation were investigated. Results illustrated much increase tensile modulus of composites content HAP nano powders ratio to micro powders. Also UTS analysis of composites […]

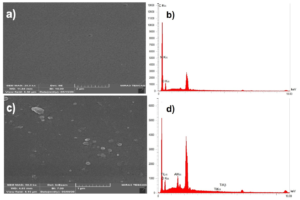

Nanocrystalline ZrO2 with particle size of about 38 nm was directly synthesized by sol-gel auto-combustion method. The overall process involved three steps: formation of homogeneous sol at 50-55°C; formation of dried gel at 110°C, and combustion of the dried gel at 400°C. Experiments revealed that ZrO2 dried gel derived from glycine (Fuel) and nitrate sol […]

This study aimed to use D-optimal combined design, and partial least squares discriminate analysis (PLS-DA) to investigate the mechanical properties, and chemical compatibilities of improved epoxy nanocomposites by nano TiO2/Al2O3. Experimental design of adhesion, and wedge bend properties led the results into the optimum values of TiO2= 0.66%, Al2O3= 1.33%, dispersant= 0.000017%. The variable importance […]