Experimental prediction of flow boiling heat transfer coefficient of Water and Copper Oxide nanofluid using ANNOVA technique

Authors

Abstract

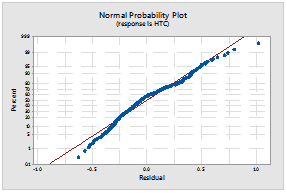

In the present work the flow boiling charecteristics of CuO/water nanofluid were studied experimentally and the statistical as well as regression analysis were conducted to asses the flow boiling heat transfer coefficient and the influencing parameters. For this, CuO/water nanofluid was prepared by two step procedure for the particle concentration of 0.001%, 0.005%, and 0.01 % respectively. The experiments were conducted by varying the heat flux and mass flux ranging from of 50-200 kW/m2 and 380-955 kg/s-m2, respectively for water and CuO/water nanofluids. All the experiments were conducted for the same temperature of water at heater inlet. A full factorial multi-level design approach was used to design the experiments by considering the heat flux, mass flux and particle concentration are key influence parameters. Results showed that the boiling heat transfer is increases with mass flux and heat flux for both water and nanofluids. Furthermore, increasing the nanoparticle concentration enhances the flow boiling heat transfer rate and lowers the wall temperature. It is observed that at a mass flux of 954.29 kg/s-m2, the maximum decrease in wall superheat is 18.66 % for 0.01% CuO/water nanofluid. From statistical analysis, it is noticed that the aforementioned factors were statistically significant. Furthermore, heat flux has a considerable influence on the boiling heat transfer coefficient, which is followed by mass flux and particle concentration. The heat transfer coefficient was predicted using a simplified quadratic model, which was found to be in good agreement with the experimental results.

Graphical Abstract

Keywords

- Particle Concentrations

- Heat Transfer Coefficient

- CuO/water Nanofluid

- Flow Boiling Curve

- Heat Flux

- Mass Flux

References

[1] Choi S. U. S., Eastman J. A., (1995), Enhancing thermal conductivity of fluids with nanoparticles. ASME Int. Mech. Cong. San Francisco. 951135.

[2] Talebi M. H., Kalantar V., Nazari M. R., Kargarsharifabad H., (2019), Experimental investigation of the forced convective heat transfer of hybride Cu/Fe3O4 nanofluides. 8: 229–238.

[3] Razaghi M., Esfahani A. A., KargarSharifabad H., (2021), Experimental Investigation of the Fe3O4 nanofluid heat transfer in a helical coil. J. Thermophys. Heat Transf. 35: 1–11.

[4] Dibaei Bonab M. H., Shafii M. B., Nobakhti M. H., (2015), Experimental and numerical investigation of fully developed forced convection of water-based Fe3O4 nanofluid passing through a tube in the presence of an alternating magnetic field. Adv. Mech. Eng.7: 1–9.

[5] Dibaei M., Kargarsharifabad H., (2016), New achievements in Fe3O4 nanofluid fully developed forced convection heat transfer under the effect of a magnetic field: An experimental study. J. Heat Mass Transf. Res. 4: 1–12.

[6] Sarafraz M. M. (2013), Experimental investigation on pool boiling heat transfer to formic acid, propanol and 2-butanol pure liquids under the atmospheric pressure. J. Appl. Fluid Mech.6: 73–79.

[7] Kim S. J., Bang I. C., Buongiorno J., W. Hu L., (2007), Surface wettability change during pool boiling of nanofluids and its effect on critical heat flux. Int. J. Heat Mass Transf. 50: 4105–4116.

[8] Sarafraz M. M., Hormozi F., (2014), Convective boiling and particulate fouling of stabilized CuO-ethylene glycol nanofluids inside the annular heat exchanger. Int. Commun. Heat Mass Transf. 53: 116-123-129.

[9] Salari E., Peyghambarzadeh M., Sarafraz M. M., Hormozi F., (2016), Boiling heat transfer of alumina nano-fluids: Role of nanoparticle deposition on the boiling heat transfer coefficient. Period. Polytech. Chem. Eng. 60: 252–258.

[10] Zangeneh A., Peyghambarzadeh S. M., Bayat A., Vatani A., (2020), Application of general multilevel factorial design approach in forced convection and subcooled flow boiling heat transfer to CuO/water nanofluids. J. Mol. Liq. 313: 113502.

[11] Modak M., Chougule S. S., Sahu S. K., (2018), An experimental investigation on heat transfer characteristics of hot surface by using CuO-Water nanofluids in circular jet impingement cooling. J. Heat Transfer. 140: 1.

[12] Sarafraz M. M., Hormozi F., Peyghambarzadeh S. M., Vaeli N., (2015), Upward flow boiling to DI-water and Cuo nanofluids inside the concentric annuli. J. Appl. Fluid Mech. 8: 651–659.

[13] Heris S. Z., Nassan T. H., Noie S. H., (2011), CuO/Water nanofluid convective heat transfer through square duct under uniform heat flux. Int. J. Nanosci. Nanotech. 7: 111-120.

[14] Guangbin Y., (2016), Experimental research on heat transfer characteristics of CuO nanofluid in adiabatic condition. J. Nanomater. 2016: Article ID 3693249.

[15] Sahin B., Manay E., Akyurek E. F., (2015), An experimental study on heat transfer and pressure drop of CuO-Water nanofluid. J. Nanomater. 2015: Article ID 790839.

[16] Nikkhah V., Sarafraz M. M., Hormozi F., (2015), Application of spherical copper oxide (II) water nano-fluid as a potential coolant in a boiling annular heat exchanger. Chem. Biochem. Eng. Quart. 29: 405–415.

[17] Yang X. F., Liu Z. H., (2012), Flow boiling heat transfer in the evaporator of a loop thermosyphon operating with CuO based aqueous nanofluid. Int. J. Heat Mass Transf. 55: 7375–7384.

[18] Abedini E., Zarei T., Afrand M., Wongwises S., (2017), Experimental study of transition flow from single phase to two phase flow boiling in nanofluids. J. Mol. Liq. 231: 11–19.

[19] Mangrulkar C. K., Kriplani V. M., Dhoble A. S., (2015), Experimental investigation of convective heat transfer enhancement using alumina/water and copper oxide/water nanofluids. Therm. Sci.2015: 1681–1692.

[20] Heris S. Z., Etemad S. G., Esfahany M. N., (2006), Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int. Commun. Heat Mass Transf. 33: 529–535.

[21] Bejjam R. B., Kiran Kumar K., Balasubramanian K., (2019), Experimental studies on nanofluid-based rectangular natural circulation loop. J. Therm. Sci. Eng. Appl.11: 041006 (10 pages).

[22] Sarafraz M. M., Abad A. T. K., (2019), Statistical and experimental investigation on flow boiling heat transfer to carbon nanotube-therminol nanofluid. Phys. A Stat. Mech. Appl. 536: Article ID. 122505.

[23] Patra N., (2017), Delay in DNB for flow boiling of diluted oxide based nanofluids. Exp. Therm. Fluid Sci. 89: 211–218.

[24] Patra N., Ghosh P., Singh R. S., Nayak A., (2019), Flow visualization in dilute oxide based nanofluid boiling. Int. J. Heat Mass Transf. 135: 331–344.

[25] Mukherjee S., Jana S., Chandra Mishra P., Chaudhuri P., Chakrabarty S., (2021), Experimental investigation on thermo-physical properties and subcooled flow boiling performance of Al2O3/water nanofluids in a horizontal tube. Int. J. Therm. Sci. 159: Article 106581.

[26] Sudheer S. V. S., Kiran Kumar K., Balasubramanian K., (2019), Experimental studies of heat transfer and flow regimes during flow boiling of water and alumina nanofluids at different heat and mass fluxes. Proc. Inst. Mech. Eng. Part C. J. Mech. Eng. Sci. 233: 7155–7169.

[27] Nagireddy D. D., Rao Chalamalasetti R., Kumar Kupireddi S., (2021), Thermal performance of natural circulation loop filled with Al2O3/Water nanofluid. Int. J. Nano Dimens. 12: 272-278.

[28] Azghandi O. R., Maghrebi M. J., Teymourtash A. R., (2021), Investigation and optimization of heat transfer coefficient of MWCNTs-Water nanofluids in a plate heat exchanger. Int. J. Nano Dimens. 12: 104–112.

[29] Lakhawat G. P., (2017), Effect of nonionic surfactant additives on the performance of nanofluid in the heat exchanger. Int. J. Nano Dimens. 8: 18–30.

[30] Prajapati O. S., Rohatgi N., (2014), Flow boiling heat transfer enhancement by using ZnO-water Nanofluids. Sci. Technol. Nucl. Install. 2014: Article ID 890316.

[31] Setoodeh H., Keshavarz A., Ghasemian A., Nasouhi A., (2015), Subcooled flow boiling of alumina/water nanofluid in a channel with a hot spot: An experimental study. Appl. Therm. Eng. 90: 384–394.

[32] El-Maghlany W. M., Hanafy A. A., Hassan A. A., El-Magid M. A., (2016), Experimental study of Cu-water nanofluid heat transfer and pressure drop in a horizontal double-tube heat exchanger. Exp. Therm. Fluid Sci. 78: 100-111.

[33] Wan Z., Deng J., Li B., Xu Y., Wang X., Tang Y., (2015), Thermal performance of a miniature loop heat pipe using water-copper nanofluid. Appl. Therm. Eng. 78: 712–719.

[34] Sarafraz M. M., Hormozi F., (2014), Forced convective and nucleate flow boiling heat transfer to alumina nanofluids. Period Polytech. Chem. Eng. 58: 37–46.

[35] Chavan D., Pise P. A. T., (2013), Experimental investigation of convective heat transfer of Al2O3/water nanofluid in cirular pipe. 6: 3–7.

[36] Sarafraz M. M., Hormozi F., (2016), Comparatively experimental study on the boiling thermal performance of metal oxide and multi-walled carbon nanotube nanofluids. Powder Technol. 287: 412-430.

[37] Wang Y., Su G. H., (2016), Experimental investigation on nanofluid flow boiling heat transfer in a vertical tube under different pressure conditions. Exp. Therm. Fluid Sci. 77: 116–123.

[38] Azizifar Sh., Ameri M., Behroyan I., (2019), Experimental investigation of subcooled flow boilling of water/TiO2 nanofluide in horizental metal tube. Heat and Mass Trans. 57: 1499-1511.