Effect of coating operating parameters on electrode physical characteristics and final electrochemical performance of lithium-ion batteries

- Warwick Manufacturing Group, University of Warwick, Coventry, CV4 7AL, GB London South Bank University, London, SE1 0AA, GB The Faraday Institution, Harwell Science and Innovation Campus, Didcot, GB

- Warwick Manufacturing Group, University of Warwick, Coventry, CV4 7AL, GB The Faraday Institution, Harwell Science and Innovation Campus, Didcot, GB

Published in Issue 2022-03-04

How to Cite

Román-Ramírez, L. A., Apachitei, G., Faraji-Niri, M., Lain, M., Widanage, D., & Marco, J. (2022). Effect of coating operating parameters on electrode physical characteristics and final electrochemical performance of lithium-ion batteries. International Journal of Energy and Environmental Engineering, 13(3 (September 2022). https://doi.org/10.1007/s40095-022-00481-w

HTML views: 4

PDF views: 68

Abstract

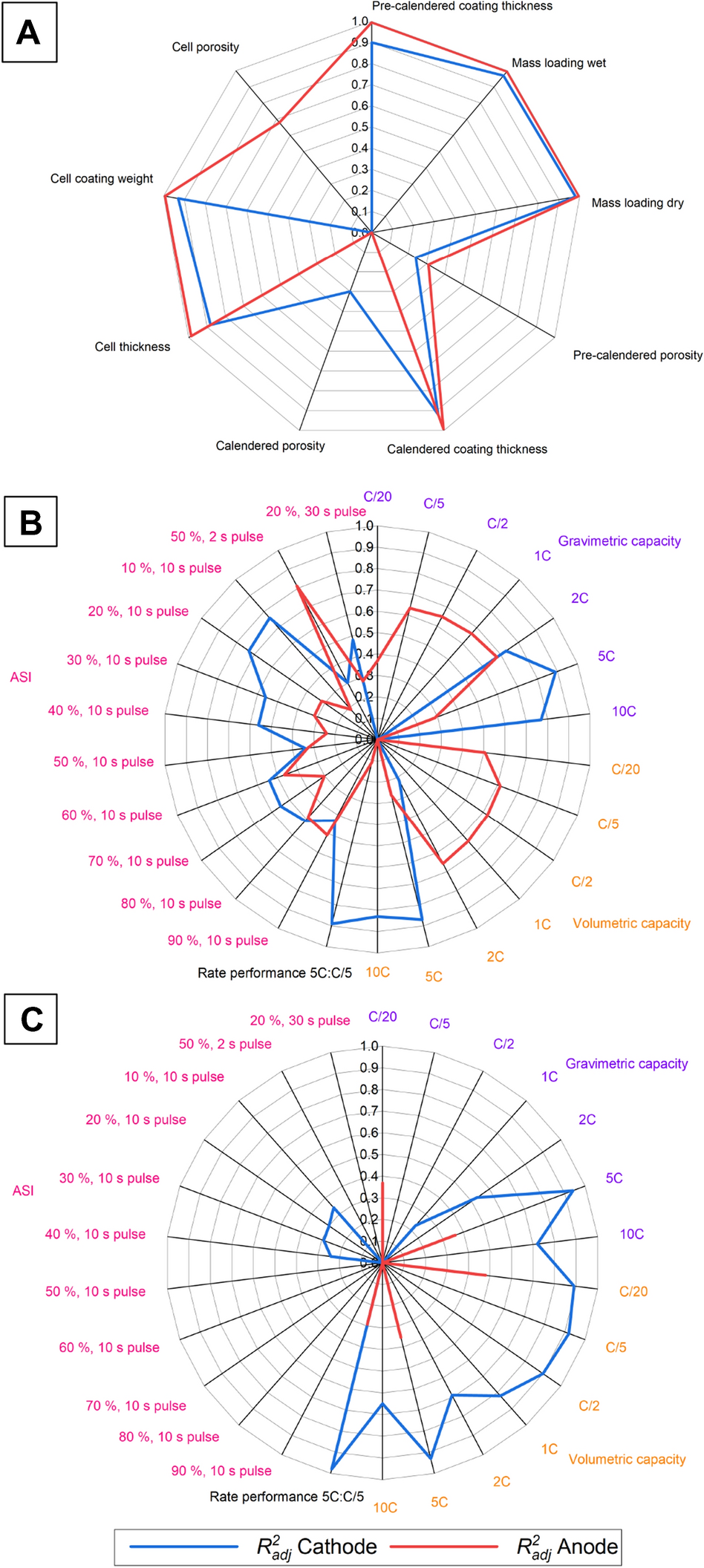

Abstract The effect of coating parameters of NMC622 cathodes and graphite anodes on their physical structure and half-cell electrochemical performance is evaluated by design of experiments. Coating parameters include the coater comma bar gap, coating ratio and web speed. The electrochemical properties studied are gravimetric and volumetric capacity, rate performance, areal specific impedance (ASI) and C-rate. Differences in the manufacturing effects on the electrode physical structure and electrochemical performance are observed between the electrodes and are modelled by linear regression. The effect of cell coating weight and porosity on half-coin cell electrochemical performance is also evaluated by linear regression. The cathode performance at high gravimetric and volumetric C-rates is mainly influenced by coating weight, whereas porosity is the only explanatory variable for volumetric C-rates of 1C and below. For anode, correlations are only found for the C/20 and 5C gravimetric and volumetric capacities and are related to coating weight. An inverse relationship between ASI and coating weight is observed for cathode, but in general the cell physical characteristics cannot completely explain the observed ASI for both electrodes. The obtained models are useful for the design and robust manufacturing of electrodes since present a quantitative relationship between the coating parameters, cell characteristics and final cell electrochemical performance.References

- Chen et al. (2019) A review of lithium-ion battery for electric vehicle applications and beyond (pp. 4363-4368) https://doi.org/10.1016/j.egypro.2019.01.783

- Wang et al. (2020) Design and management of lithium-ion batteries: A perspective from modeling, simulation, and optimization 29(6) https://doi.org/10.1088/1674-1056/ab90f8

- Foley et al. (2020) Factors affecting electric vehicle uptake: insights from a descriptive analysis in Australia 4(4) https://doi.org/10.3390/urbansci4040057

- Sanguesa et al. (2021) A review on electric vehicles: technologies and challenges 4(1) (pp. 372-404) https://doi.org/10.3390/smartcities4010022

- Meyer et al. (2020) Development and implementation of statistical methods for quality optimization in the large-format lithium-ion cells production 8(2) https://doi.org/10.1002/ente.201900244

- Turetskyy et al. (2020) Toward data-driven applications in lithium-ion battery cell manufacturing 8(2) (pp. 1900136-1900136) https://doi.org/10.1002/ente.201900136

- Schönemann et al. (2019) Multiscale simulation approach for production systems: application to the production of lithium-ion battery cells 102(5–8) (pp. 1373-1390) https://doi.org/10.1007/s00170-018-3054-y

- Primo et al. (2021) Understanding the calendering processability of Li(Ni0.33Mn0.33Co0.33)O2-based cathodes https://doi.org/10.1016/j.jpowsour.2020.229361

- Kwade et al. (2018) Current status and challenges for automotive battery production technologies 3(4) (pp. 290-300) https://doi.org/10.1038/s41560-018-0130-3

- Wang et al. (2020) Effects of the mixing sequence on making lithium ion battery electrodes 167(10) https://doi.org/10.1149/1945-7111/ab95c6

- Konda et al. (2020) Comprehensive effort on electrode slurry preparation for better electrochemical performance of LiFePO4 battery https://doi.org/10.1016/j.jpowsour.2020.228837

- Hawley and Li (2019) Beneficial rheological properties of lithium-ion battery cathode slurries from elevated mixing and coating temperatures https://doi.org/10.1016/j.est.2019.100994

- Meyer et al. (2020) Heated calendering of cathodes for lithium-ion batteries with varied carbon black and binder contents 8(2) https://doi.org/10.1002/ente.201900175

- Westphal et al. (2017) Influence of high intensive dry mixing and calendering on relative electrode resistivity determined via an advanced two point approach (pp. 76-85) https://doi.org/10.1016/j.est.2017.02.001

- Román-Ramírez et al. (2021) Understanding the effect of coating-drying operating variables on electrode physical and electrochemical properties of lithium-ion batteries https://doi.org/10.1016/j.jpowsour.2021.230689

- Duquesnoy et al. (2021) Machine learning-based assessment of the impact of the manufacturing process on battery electrode heterogeneity https://doi.org/10.1016/j.egyai.2021.100090

- Keppeler et al. (2021) The role of pilot lines in bridging the gap between fundamental research and industrial production for lithium-ion battery cells relevant to sustainable electromobility: a review 9(8) https://doi.org/10.1002/ente.202100132

- Niri et al. (2022) Quantifying key factors for optimised manufacturing of Li-ion battery anode and cathode via artificial intelligence https://doi.org/10.1016/j.egyai.2021.100129

- Turetskyy et al. (2021) Battery production design using multi-output machine learning models (pp. 93-112) https://doi.org/10.1016/j.ensm.2021.03.002

- Myers et al. (2016) Response surface methodology: process and product optimization using designed experiments Wiley

- Román-Ramírez et al. (2022) Experimental data of cathodes manufactured in a convective dryer at the pilot-plant scale, and charge and discharge capacities of half-coin lithium-ion cells https://doi.org/10.1016/j.dib.2021.107720

- Román-Ramírez, L.A., Marco, J.: Design of experiments applied to lithium-ion batteries: A literature review. Submitted, (2021).

- Cox and Reid (2000) CRC Press https://doi.org/10.1201/9781420035834

- Lain and Kendrick (2021) Understanding the limitations of lithium ion batteries at high rates https://doi.org/10.1016/j.jpowsour.2021.229690

- Argonne National Laboratory: Modeling the performance and cost of lithium-ion batteries for electric-drive vehicles. Department of Energy, U.S. (2012).

- Schmidt et al. (2020) Modeling the impact of manufacturing uncertainties on lithium-ion batteries 167(6) https://doi.org/10.1149/1945-7111/ab798a

- Tian et al. (2019) Quantifying the factors limiting rate performance in battery electrodes 10(1) (pp. 1-11) https://doi.org/10.1038/s41467-019-09792-9

- Saraka et al. (2020) Correlating processing conditions to short- and long-range order in coating and drying lithium-ion batteries 3(12) (pp. 11681-11689) https://doi.org/10.1021/acsaem.0c01305

- Gallagher et al. (2011) Simplified calculation of the area specific impedance for battery design 196(4) (pp. 2289-2297) https://doi.org/10.1016/j.jpowsour.2010.10.020

10.1007/s40095-022-00481-w

10.1007/s40095-022-00481-w