Flare performance modeling and set point determination using artificial neural networks

- Dan F. Smith Department of Chemical Engineering, Lamar University, Beaumont, TX, 77710, US

- Department of Chemistry and Biochemistry, Lamar University, Beaumont, TX, 77710, US

- Mechanical Engineering, Lamar University, Beaumont, TX, 77710, US

Published in Issue 2019-08-13

How to Cite

Damodara, V. D., Alphones, A., Chen, D. H., Lou, H. H., Martin, C., & Li, X. (2019). Flare performance modeling and set point determination using artificial neural networks. International Journal of Energy and Environmental Engineering, 11(1 (March 2020). https://doi.org/10.1007/s40095-019-00314-3

PDF views: 49

HTML views: 11

Abstract

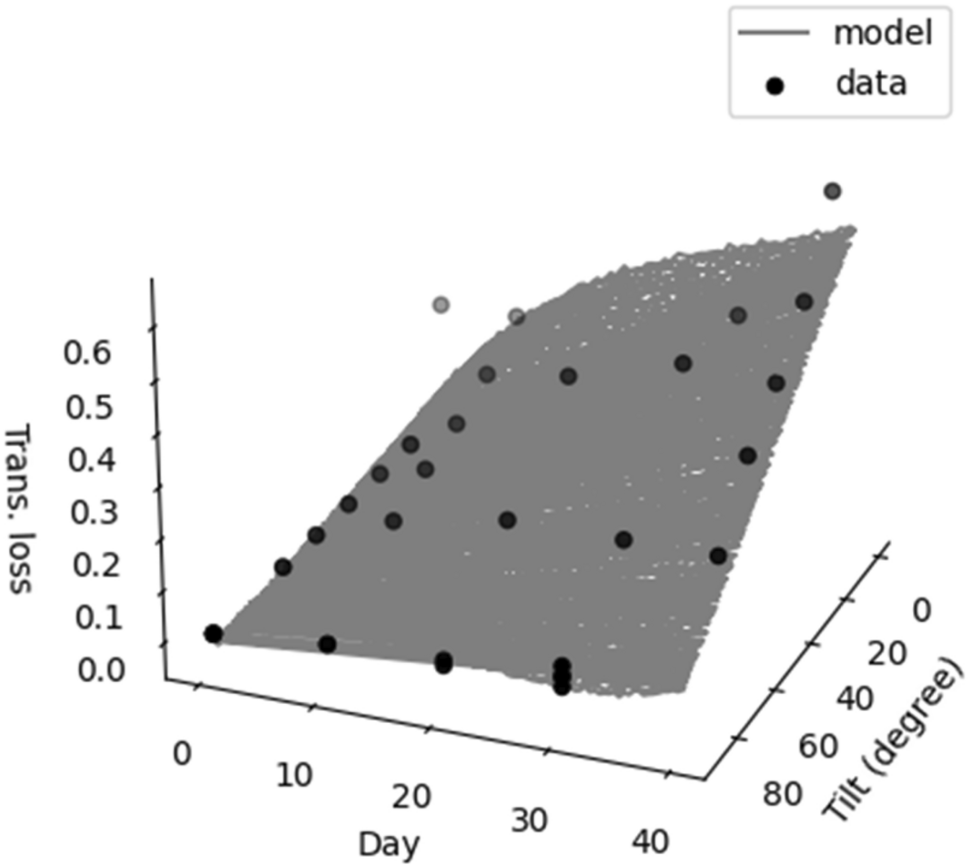

Abstract Current EPA regulations mandate a minimum combustion zone heating value of 270 BTU/scf and a net heating value dilution parameter of NHV dil ≥ 22 BTU/ft 2 for all steam/air/non-assisted flares while maintaining a high combustion efficiency (CE). To achieve the target performance along with satisfying the EPA regulations, it is necessary to understand the influence of various operating parameters. Studying the effect of operating parameters through experiments is both expensive and time consuming. It is more cost effective to use validated models to guide flare operations. In this study, controlled flare test data conducted from 1983 to 2014 with a wide range of exit velocities, heating values, and fuel compositions have been modeled. The purpose of this study is to develop models that can be robustly used in the industry to achieve the desired CE without visible emissions (smoke). Steam-/air-assist rates, exit velocity, and the vent gas composition, which can be either controlled or measured in flare operations, are used as independent variables in the models. Neural network (NN) models were developed for the air-assisted, steam-assisted, and non-assisted flares using various types of fuels like propylene, propane, natural gas, methane, and ethylene. The flare performance models such as CE and opacity were developed using neural network toolbox in MATLAB. NN models for steam and air-assisted flare tests are in good agreement with experimental data and have been demonstrated by the average correlation coefficient of 0.95 and 0.97 for air-assisted and steam-assisted flare data, respectively. The very low mean absolute errors of 1.1% and 1.4% for air-assisted and steam-assisted flare data, respectively, also indicate the robustness of the NN models. 2-D and 3-D contour plots are presented to show the effect of key operating parameters. The set points (amount of steam/air/make-up fuel required) at the Incipient Smoke Point (ISP) and for Smokeless Flaring (SLF) have been developed based on the neural network models performed in this study. Desirable operating inputs can be set for the ISP and for SLF (Opacity ≤ Opacity ISP ) subject to heating value constraints (NHV dil ≥ 22 BTU/ft 2 & NHV CZ ≥ 270 BTU/scf) with a high CE (≥ 96.5%) for the 1984 EPA and 2010 TCEQ flare study test cases.Keywords

- Combustion efficiency,

- Opacity,

- Neural network,

- Incipient smoke point

References

- Strosher (2000) Characterization of emissions from diffusion flare systems https://doi.org/10.1080/10473289.2000.10464218

- Marrero et al. (2016) Estimating emissions of toxic hydrocarbons from natural gas production sites in the Barnett Shale Region of Northern Texas https://doi.org/10.1021/acs.est.6b02827

- RTI International. Emissions estimation protocol for petroleum refineries. Research Triangle Park, NC (2015). https://www3.epa.gov/ttn/chief/efpac/protocol/Protocol Report 2015.pdf

- The World Bank.: Global gas flaring reduction partnership (GGFR). Available at:

- http://www.worldbank.org/en/programs/gasflaringreduction

- . Accessed 17 Apr 2019

- Bader et al. (2011) Selecting the proper flare systems 107(7) (pp. 45-50)

- Ismail and Umukoro (2016) Modelling combustion reactions for gas flaring and its resulting emissions https://doi.org/10.1016/j.jksues.2014.02.003

- Russ Nettles, Russ Nettles, Air Quality Division.: Texas commission on environmental quality (TCEQ) 2010 flare study & supplemental flare operations training (2014). Available at:

- https://www.cleanairact.org/events/documents/NETTLES.pdf

- . Accessed 11 Aug 2019

- Stohl et al. (2013) Black carbon in the Arctic: the underestimated role of gas flaring and residential combustion emissions https://doi.org/10.5194/acp-13-8833-2013

- Caulton et al. (2014) Toward a better understanding and quantification of methane emissions from shale gas development https://doi.org/10.1073/pnas.1316546111

- Schneising et al. (2014) Remote sensing of fugitive methane emissions from oil and gas production in North American tight geologic formations https://doi.org/10.1002/2014ef000265

- Farina, M.F.: Flare gas reduction: recent global trends and policy considerations. General Electric Company (2011)

- Weyant et al. (2016) Black carbon emissions from associated natural gas flaring https://doi.org/10.1021/acs.est.5b04712

- Gvakharia et al. (2017) Methane, black carbon, and ethane emissions from natural gas flares in the Bakken Shale, North Dakota https://doi.org/10.1021/acs.est.6b05183

- Elvidge et al. (2016) Methods for global survey of natural gas flaring from visible infrared imaging radiometer suite data https://doi.org/10.3390/en9010014

- Elvidge et al. (2018) The potential role of natural gas flaring in meeting greenhouse gas mitigation targets https://doi.org/10.1016/j.esr.2017.12.012

- Office of the Federal Register, N.A. and R.A. 83 FR 15458: National emission standards for hazardous air pollutants and new source performance standards: petroleum refinery sector amendments. Federal Register

- 83

- (69) (2018). Available at:

- https://www.govinfo.gov/app/details/FR-2018-04-10/2018-06223

- . Accessed 11 Aug 2019

- US Environmental Protection Agency.: Parameters for properly designed and operated flares (2012)

- U.S. EPA.: Review & peer review of “Parameters for properly designed and operated flares” documents. Available at:

- https://www.epa.gov/stationary-sources-air-pollution/review-peer-review-parameters-properly-designed-and-operated-flares

- . Accessed 11th Aug 2019

- Baukal and Schwartz (2001) CRC Press https://doi.org/10.1201/9781420038699

- Walls, S., Knauf, M.: NSPS Subpart Ja flare management plan—plan elements and lessons learned. in: american fuel and petrochemical manufacturers. In: AFPM—Environmental Conference 2014: Enforcement Initiatives (2014)

- EPA: Enforcement targets flaring efficiency violations. Enforcement Alert,

- 10

- (5). EPA 325-F-012-002 (2012)

- Unknown (2015) Petroleum refinery sector risk and technology review and new source performance standards (pp. 75178-75229)

- Zeng et al. (2016) Validation of a new method for measuring and continuously monitoring the efficiency of industrial flares https://doi.org/10.1080/10962247.2015.1114045

- U.S. EPA.: 40 CFR Part 60: oil and natural gas sector: emission standards for new, reconstructed, and modified sources. 81(107) (2016).

- https://www.govinfo.gov/content/pkg/FR-2016-06-03/pdf/2016-11971.pdf

- Holden (2005) MACT rule will have effect on stationary engines 232(10) (pp. 31-33)

- Unknown (2012) Oil and natural gas sector: new source performance standards and national emission standards for hazardous air pollutants reviews Final rule 77(159) (pp. 49-490)

- Alphones, A., Damodara, V., Chen, D.H., Fortner, E.C., Evans, S., Johnson, M.R.: Response surface modeling of flare performance and characterization of the incipient smoke point. In 2015 AIChE annual meeting. Paper no. 199e (2015)

- Chen and Alphones (2019) Characterization of the incipient smoke point for steam-/air-assisted and nonassisted flares 69(1) (pp. 119-130) https://doi.org/10.1080/10962247.2018.1525443

- Singh, K.D., Gangadharan, P., Dabade, T., Shinde, V., Chen, D., Lou, H.H., Richmond, P.C., Li, X.: Parametric study of ethylene flare operations using numerical simulation. Eng. Appl. Comput. Fluid Mech. (2014)

- Allen, D.T., Torres, V.M.: Texas commission on environmental quality TCEQ 2010 flare study final report (2011). Available at:

- https://www.tceq.texas.gov/assets/public/implementation/air/rules/Flare/2010flarestudy/2010-flare-study-final-report.pdf

- . Accessed 11 Aug 2019

- Clean Air Engineering, I.: Performance test of a steam-assisted elevated flare with passive FTIR-detroit final report. Marathon Petroleum Company, LP Detroit Refinery. (2010)

- Marathon Petroleum Company, L.: Performance test of a steam-assisted elevated flare with passive FTIR., Texas City, Texas (2010)

- Providence Engineering.: Technology | Flare combustion efficiency monitoring | Providence engineering. Available at:

- http://www.providenceeng.com/projects/category/technology/flare-combustion-efficiency-monitoring

- . Accessed 27 Oct 2018

- Corbin, D.J., Johnson, M.R.: Summary of flare efficiency and soot emission rate measurement results at Carleton University Energy & Emissions Research Lab: Final Report; TCEQ Project number 582-10-94307-FY14-06; Prepared for TCEQ., Ottawa, ON, Canada (2014)

- McEwen and Johnson (2012) Black carbon particulate matter emission factors for buoyancy-driven associated gas flares https://doi.org/10.1080/10473289.2011.650040

- McDaniel, M., Tichenor, B.A.: Flare efficiency study (1983)

- Aerodyne Research Mobile Laboratory.: Particulate measurements, TCEQ 2010 flare study. Available at:

- https://www.tceq.texas.gov/assets/public/implementation/air/rules/Flare/2010flarestudy/2010-flare-study-final-appendices-particulates.pdf

- . Accessed 11 Aug 2019

- Pohl et al. (1986) Combustion efficiency of flares https://doi.org/10.1080/00102208608923934

- Damodara et al. (2017) Reduced combustion mechanism for C1–C4 hydrocarbons and its application in computational fluid dynamics flare modeling https://doi.org/10.1080/10962247.2016.1268546

- Singh et al. (2014) Computational fluid dynamics modeling of laboratory flames and an industrial flare https://doi.org/10.1080/10962247.2014.948229

- Singh et al. (2012) Computational fluid dynamics modeling of industrial flares operated in stand-by mode https://doi.org/10.1021/ie300639f

- MATLAB.: Multilayer neural network using backpropagation algorithm (2015)

- Madsen et al. (2004) Soc. Ind. Appl

- Prechelt (2012) Early stopping—but when? https://doi.org/10.1007/978-3-642-35289-8-5

- Leven (1996) The roots of backpropagation: From ordered derivatives to neural networks and political forecasting 9(3) (pp. 543-544) https://doi.org/10.1016/0893-6080(96)90015-5

- Rumelhart et al. (1995) Backpropagation: the basic theory (pp. 1-34) Lawrence Erlbaum Associates Inc

- Rumelhart et al. (1986) Learning representations by back-propagating errors https://doi.org/10.1038/323533a0

- Hagan and Menhaj (1994) Training feedforward networks with the Marquardt algorithm https://doi.org/10.1109/72.329697

- Rojas (1996) Neural networks: a systematic introduction https://doi.org/10.1016/0893-6080(94)90051-5

- Arbib et al. (1994) Neural networks algorithms, applications (pp. 209-212) https://doi.org/10.1016/0893-6080(94)90073-6

- Gershenson (2003) Artificial neural networks for beginners https://doi.org/10.1093/icesjms/fsp009

- Vega-Carrillo et al. (2006) Neutron spectrometry using artificial neural networks https://doi.org/10.1016/j.radmeas.2005.10.003

- Wang et al. (2008) Solar flare forecasting model supported with artificial neural network techniques https://doi.org/10.1016/j.asr.2007.06.070

- Kahforoshan, D., Fatehifar, E., Babalou, A.A., Ebrahimin, A.R., Elkamel, A., Soltanmohammadzadeh, J.S.: Modeling and evaluation of air pollution from a gaseous flare in an oil and gas processing area. In: WSEAS conferences in Santander (2008)

- Bellasio, R. (2012) Enviroware srl. Modelling industrial flares impacts (2012). Available at:

- https://www.enviroware.com/modelling-industrial-flares-impacts/ModellingIndustrialFlaresImpacts.pdf

- . Accessed 11 Aug 2019

- Willis (2015) Flare efficiency estimator and case studies https://doi.org/10.2166/9781780404882

- Tamas, W.W., Notton, G., Paoli, C., Voyant, C., Nivet, M.L., Balu, A.: Urban ozone concentration forecasting with artificial neural network in {Corsica}. arXiv1306.0897 [cs]. (2013)

- L. Ou, H.C.: Updated vented, flaring, and fugitive greenhouse gas emissions for crude oil production in the GREET1_2018 model. Argonne Natl. Lab. Argonne, IL, 1-9. (2014)

- Hsu et al. (1995) Artificial neural network modeling of the rainfall-runoff process https://doi.org/10.1029/95wr01955

- Benardos and Vosniakos (2007) Optimizing feedforward artificial neural network architecture https://doi.org/10.1016/j.engappai.2006.06.005

- Hagan and Demuth (1999) Neural networks for control https://doi.org/10.1109/acc.1999.786109

10.1007/s40095-019-00314-3

10.1007/s40095-019-00314-3